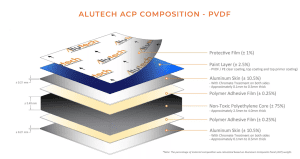

The durability of aluminum composite panels, which makes it a credible material for interior and exterior applications, may be one of the reasons why developers are drawn to this material. ACP, literally translated into aluminum composite panels, is a merge of two constituent materials that contribute to its stability. It is known as a sandwich panel for the same reason. The illustration below is a visualization of the components of this material:

Originally, ACP was created as a material for signages before it was developed and repurposed as a building material for other architectural needs like wall claddings, interior and exterior walls, partitions, and false ceilings. Modifications were made to the material such that its overall quality levels or exceeds other cladding materials. Some of the advantages of ACP are durability, weather resistance, sound reducing and insulation properties, easy maintenance, and torsion strength. But what is ACP really made of?

There are 5 components that make up ACP. Two of which contribute to its rigidity and durability. The two main elements are the aluminum layers and the core element. Note that aluminum skin determines the strength of the material so the thicker the core is, the better. Normally the thickness varies from 0.20-0.25 aluminum coil thickness, with the former usually used for interior purposes, while the latter is commonly used for exterior applications. In the illustration above, the polyethylene core is sandwiched between the polymer adhesive film and aluminum skin on both sides. The polymer adhesive on both sides of the core binds it together with the aluminum skin. The paint layer shows the color of the ACP while the protective film keeps it from being scratched or dented before installation. The protective film is only removed after the cladding installation.

Aside from the general properties, it is most important to address the fire resistance of ACP, since it has been one of the most debatable topics since it was created. While all the other qualities are good, ACP should still be a reliable material for mass usage.

Nowadays, ACP is a common material in the Philippines because it protects well against the dynamic weather, and at the same time, provides a wonderful aesthetic to the exterior. With the numerous benefits that ACP has to offer, it is only right to be your next choice for exterior cladding.

For a trusted aluminum composite supplier in the Philippines, you can contact Alutech, a leading brand of ACP in the Philippines. Alutech has a variety of colors both for interior (PE) and exterior (PVDF) uses. You can check the price of aluminum composite panels by clicking here.